Ceramic heating elements

made of hotpressed silicon nitride ceramic

Heating cutters

for machine building industry

Products / Ceramic heating elements / Heating cutters

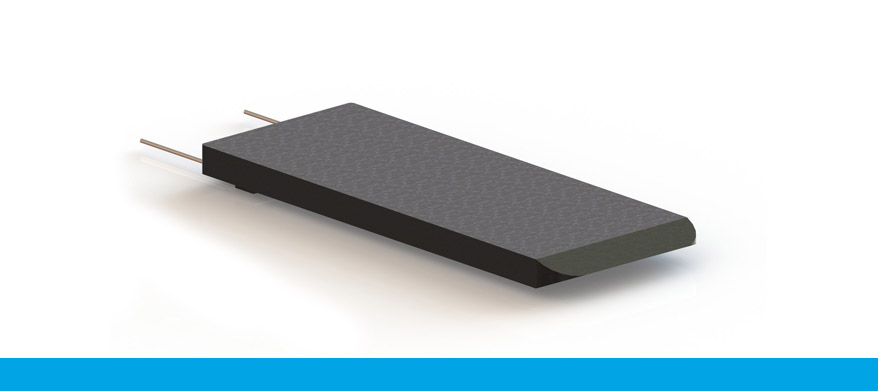

Heating cutters

Description

Ceramic heated knifes made of silicon nitride can be produced in various sizes and shapes and adjusted to fit the dimensions of the material or surface to be cut. Typical shapes are ring knifes, rectangles with cutting edges and heated rails. The good thermal conduction and the low thermal mass of the ceramic material allow extremely fast heating rates, a uniform temperature distribution and high control accuracy. The high strength of hot-pressed silicon nitride guarantees high stress resistance and excellent wear resistance at short processing times. The ceramic material is resistant to disinfectants and detergents and does not react to food in any way. We provide heated knifes for machines for operating in the open air at temperatures up to 500 °C. Performance and temperature control can be adjusted to the material and the machine.

Customized design

Our in-house designs make any modification in size, configuration or electrical power simple and convenient. Mounting-brackets and machine connections can be built and included in the delivery of heated rails and heated knifes. Processing our heating elements we can achieve flatness and dimensional tolerance of < 10 μm. In addition, various contours adjusted to the shape of materials or tools are possible. For cutting processes it is possible to grind a cutting edge and directly heat the blade.

Range of products

This is only a small selection from our product portfolio. For other variants please contact us with our product request form.

| Dimensions | Heated area | Tmax |

|---|---|---|

| 58 x 21.5 x 6.0 mm | 21.5 x 8.5 x 6.0 mm | 1 000 °C |

| 114.8 x 12.2 x 5.0 mm | 114.8 x 6.5 x 5.0 mm | 500 °C |

Advantages

Your advantages:

- Fast heating rates reduce processing time and increase Your yield through shorter cycle times

- Extremely low wear of the cutting edge

- You can eliminate preheating or reduce time for heating up Your system to few minutes

- Your machine can become smaller and lighter thanks to the reduction of mass and volume of the heating components

- You can eliminate or significantly reduce downtime that is caused by failure of heating components

Areas of application

- foil cutting

- cutting systems

- stripping

- medical technology

- drying (e. g. glue)

- metering (preheating)

- hot cutting devices

- foil welding

- sealing and seaming

- hot stamping (marking)

It is suitable for pharmacy, food, packaging material, chemical industry, cosmetics, semiluxury food, hygiene products, pet food, construction materials...